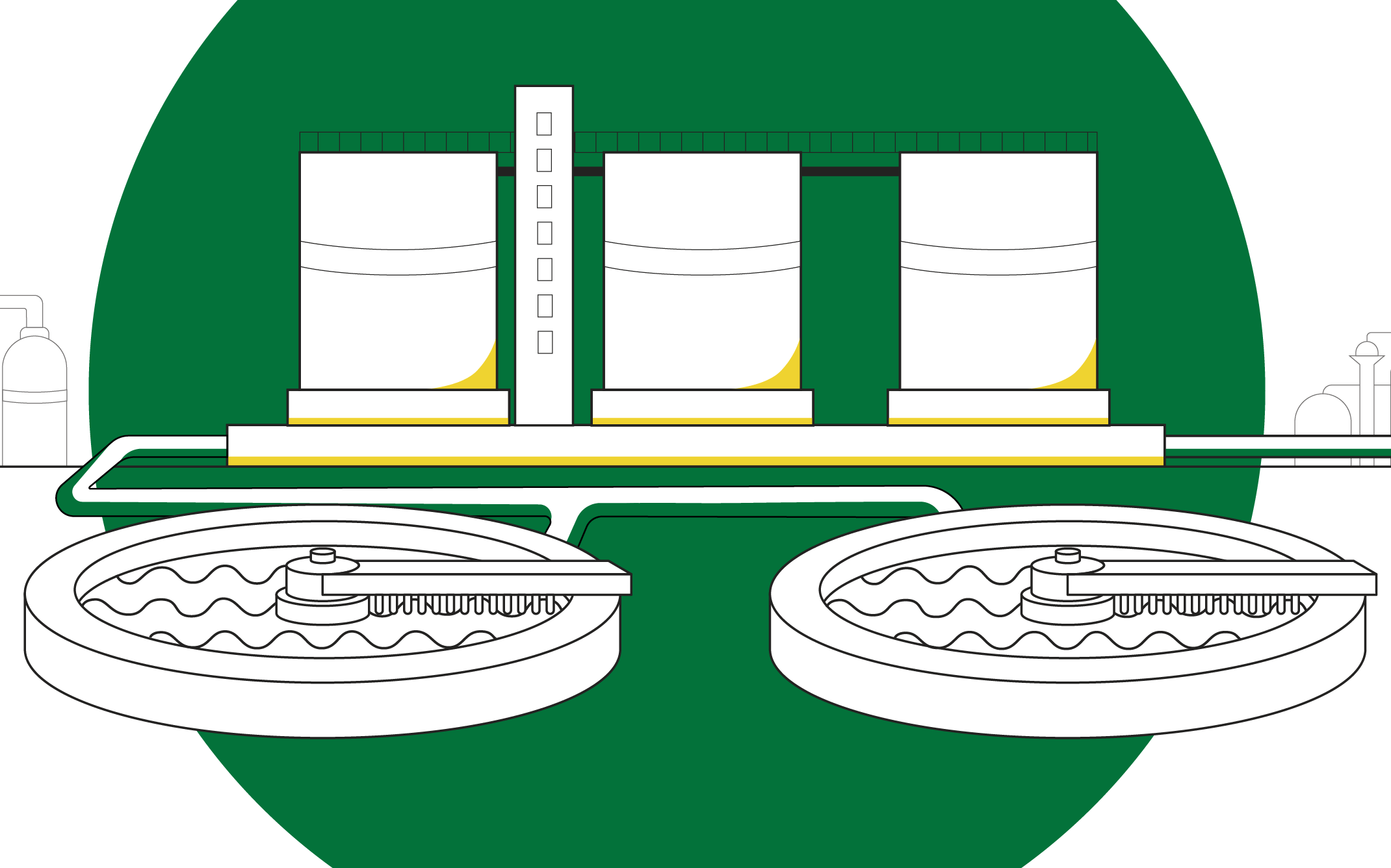

Lecoque eggs invested in a watertreatment plant

Lecoque Eggs invested in a water treatment plant to recover their wastewater. By building this plant, they reduce water consumption and only discharge purified water. This way, Lecoque eggs is making an effort for a greener future.

The wastewater first goes through several treatment steps to obtain a rainwater-quality water flow.

Coarse filtration is done first, separating all dirt particles larger than 0.5 mm from the wastewater stream. Then we go one step further. Here, the majority of suspended solids are removed from the stream. The remaining water now goes to biology. In biology, micro-organisms live and will feed on the waste products still in our water stream. After biology, the water is further filtered into rainwater-quality water using a membrane bioreactor.

To reduce our ecological footprint, we decided not to stop and discharge this water after this treatment step, but to further purify this water to drinking water quality. To further purify our rainwater-quality water stream, we use the reverse osmosis principle.

Pumping a stream of water with a constant concentration of dissolved substances at a certain pressure around a semipermeable membrane creates a pressure difference between the two sides of the membrane. As a result, water will flow through the membrane so that on the side of the highest pressure we obtain a concentrated solution of all waste substances (which we call concentrate) and on the other side of the semipermeable membrane we obtain a stream of water similar to remineralised water (which we call permeate).

With this plant, we obtain an 80% efficiency. This means that 80% of our incoming water stream becomes permeate (purified water) and 20% concentrate is discharged, containing all waste products. We then remineralise the permeate using groundwater. We do this by making a continuous mixture of 80% permeate and 20% groundwater. This remineralised water is then reused in the production process.

Other articles

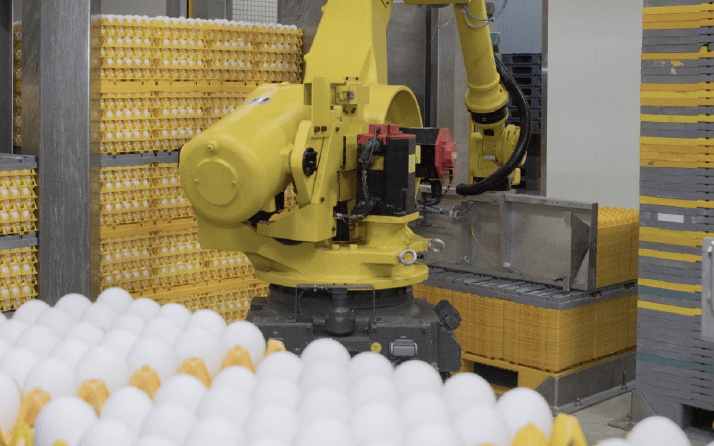

Four new robots installed at Lecoque Eggs

Lecoque Eggs installed four new robots on its hard-boiled, peeled egg production line.

Lecoque eggs invested in a new environmentally friendly cooling installation

In 2011, we at Lecoque decided to systematically replace the old cooling installations with new ammonia-based systems.

The new Lecoque generation joins the family business

The two daughters of the managers Jean-Marie Lecoque and his wife Jeannine Vanvinckenroye now work in the family-run SME.