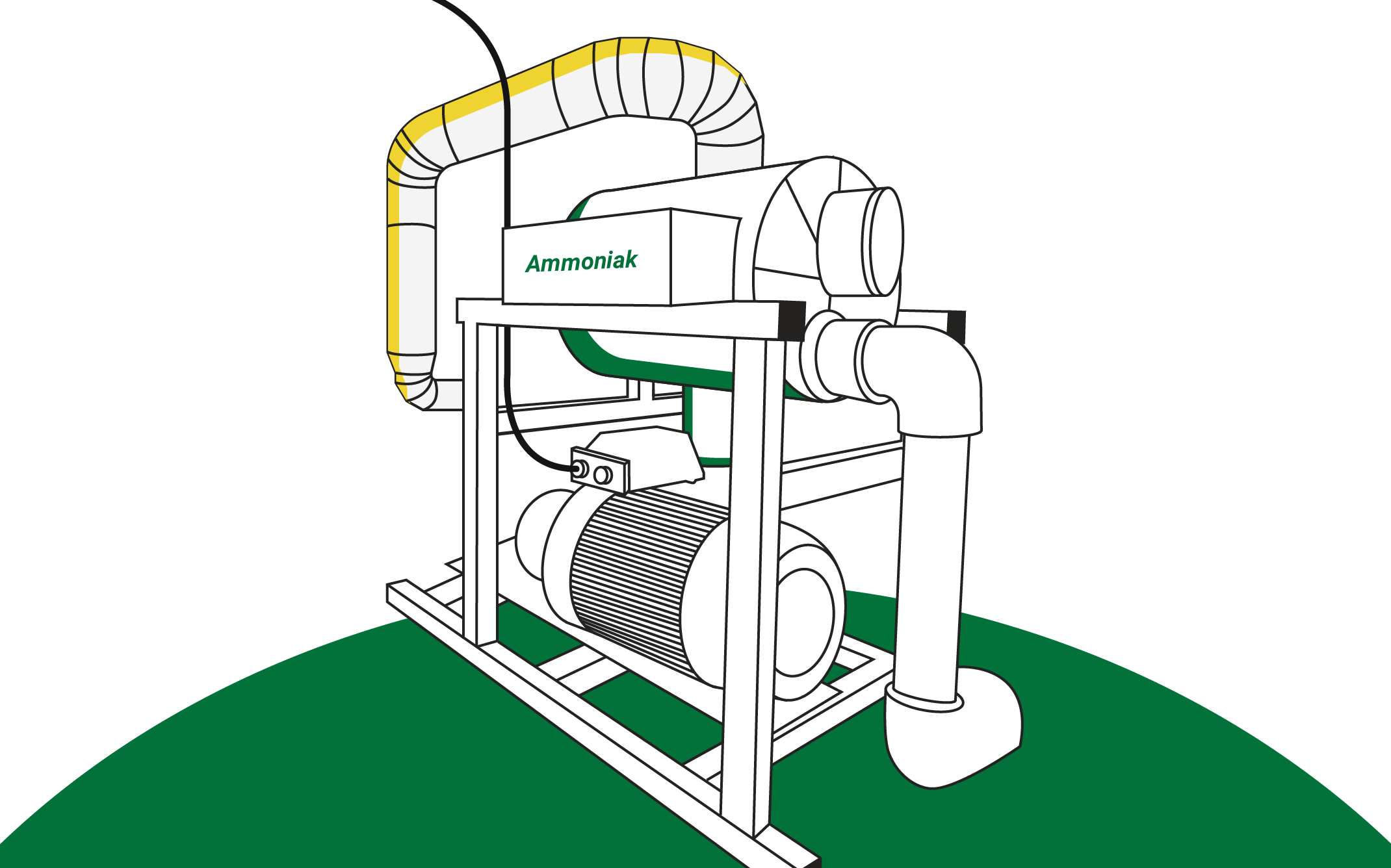

Lecoque eggs invested in a new environmentally friendly cooling installation

As a consequence of the regulations on the use of HCFCs due in 2015 (refilling HCFCs was banned from January 1st, 2015), we already decided in 2011 to systematically replace the old cooling installations with new ammonia-based systems at Lecoque.

Ammonia, along with CO2, is the most environmentally friendly and most widely used natural refrigerant. In addition, the impact on the greenhouse effect of ammonia is zero.

Our old installations of process cooling (for cooling the eggs after cooking) and refrigerators have been replaced in 2 phases to switch from using HCFKs to using ammonia.

For process cooling, the new installation was built in 2012. For refrigeration, this change was implemented in 2015.

Moreover, an additional energy recovery system was installed along with the new process cooling system. This heat surplus is used as floor heating in a storage warehouse.

Other articles

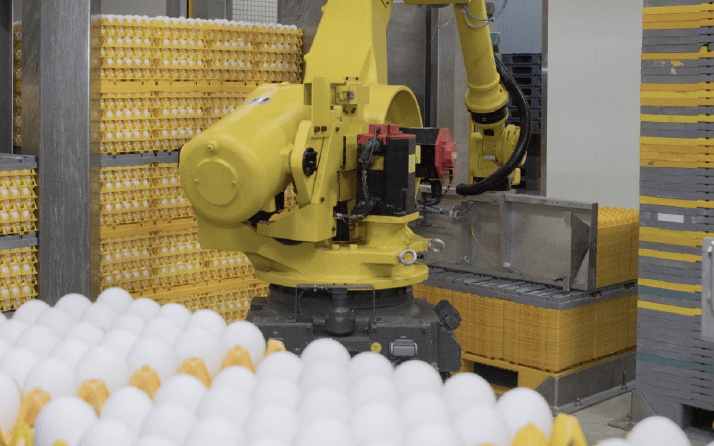

Four new robots installed at Lecoque Eggs

Lecoque Eggs installed four new robots on its hard-boiled, peeled egg production line.

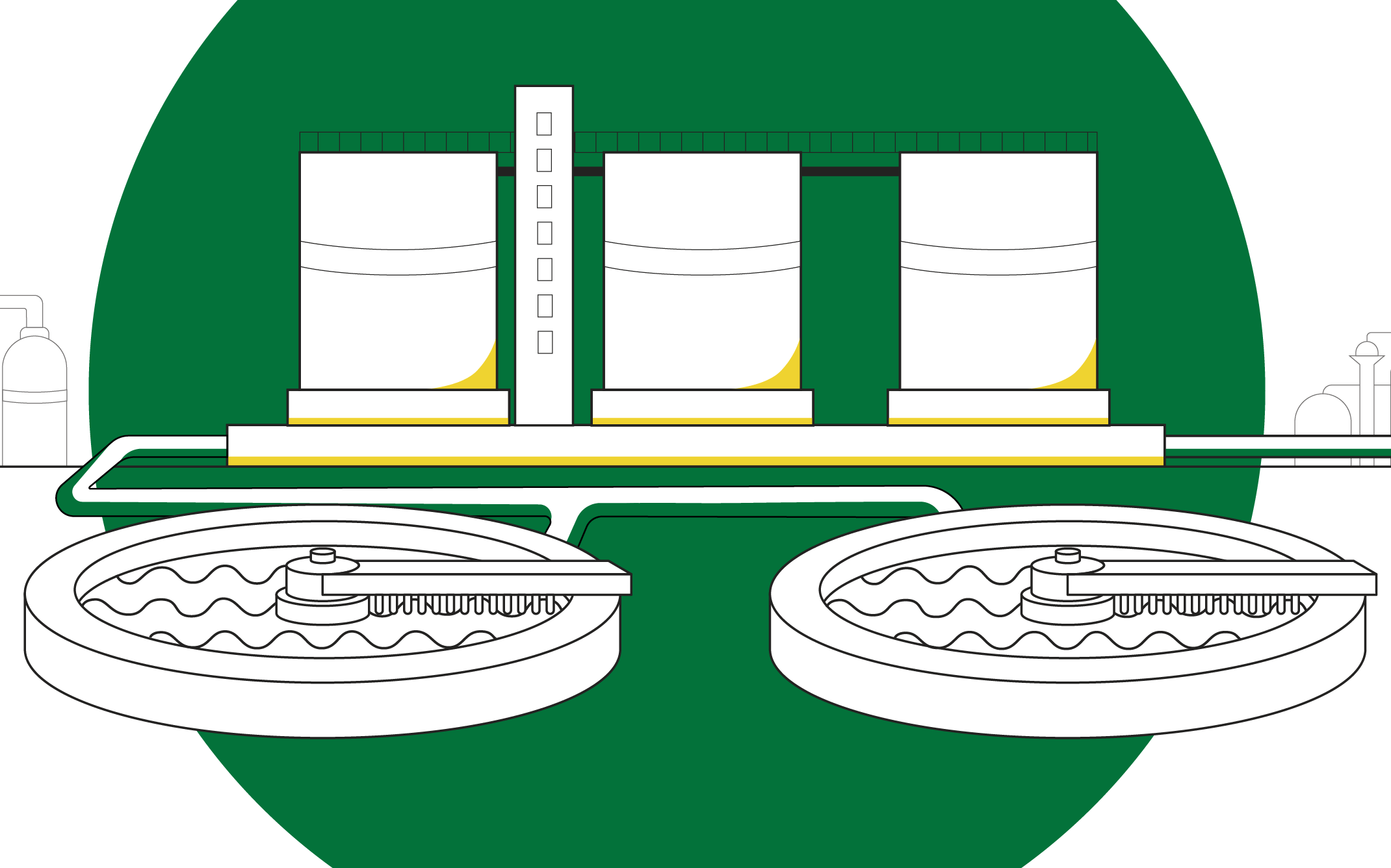

Lecoque eggs invested in a watertreatment plant

Lecoque Eggs invested in a water treatment plant to recover their wastewater.

The new Lecoque generation joins the family business

The two daughters of the managers Jean-Marie Lecoque and his wife Jeannine Vanvinckenroye now work in the family-run SME.